Air Monitoring

Air Monitoring

What is Air Monitoring?

Third party sampling and analysis for airborne asbestos fibers during an abatement project should be performed by a qualified person on behalf of the building owner or primary contractor. Air monitoring should NOT be conducted by the asbestos abatement contractor as this poses a serious conflict of interest.

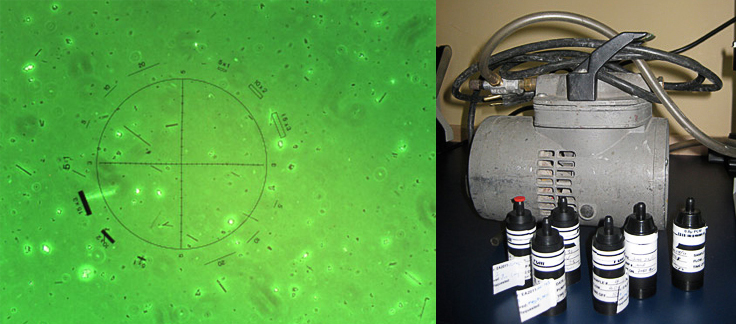

Our field technicians have been trained in microscopic analysis NIOSH 7400 Test Method to determine the concentration of fibers in the air where asbestos may pose a health risk. Air monitoring is also conducted before, during and after removal of asbestos-containing materials.

WorkSafeBC recommends that asbestos air monitoring should be performed whenever ACM is being removed, to ensure that control measures are effective when working on or removing asbestos containing materials

The four different types of

asbestos air monitoring and testing include:

1. Pre-Abatement Sampling(Background)

Air samples collected prior to commencement of abatement activities represent fiber concentrations which occur in the air during normal activities.

2. Worker Exposure Sampling(Occupational)

Tests the air in a worker’s breathing zone to determine the amount of exposure to asbestos fibres. Exposure monitoring is conducted to determine whether workers respiratory protection is adequate during abatement as per WorkSafeBC regulations.

3. Daily Abatement Sampling(Ambient)

The collection of air samples during abatement is important to all parties involved. The documentation of fiber concentrations determines if the contractor provided adequate engineering controls, work practices, and maintained barriers in order to prevent the release of fibers to outside the work area.

4. Clearance Sampling(Air Clearance)

Final clearance sampling is conducted at the completion of abatement and cleanup activities; and after visual inspections are conducted, but before any isolation and critical barriers are removed.

5. Field Blank

According to NIOSH 7400 airborne fiber counting test method and WorkSafeBC,at least two field blanks (or 10% of the total samples, whichever is greater) should accompany each set of samples. Handle field blanks in a manner representative of actual handling of associated samples in the set. Open field blank cassettes at the same time as other cassettes just prior to sampling.

Rotameter Calibration Services

WorkSafeBC requires that all air sampling equipment must be calibrated against a primary standard. Rotameters measure airflow using a ball inside a vertical tube.